MYFORD / HERCUS RECONS

60 years in the Machine Tool Reconditioning Industry

Committed to the genuine precision machine tool industry, machine tool reconditioning has been carried out by Machine Tool Automation, and parent company Hardwick & Tatam since 1963.

We have also continued to embrace the timeless Hobby Machinist industry in providing well priced reconditioning of the quality Myford, Hercus lathes, and all other workshop machine tools, for these non profit entities.

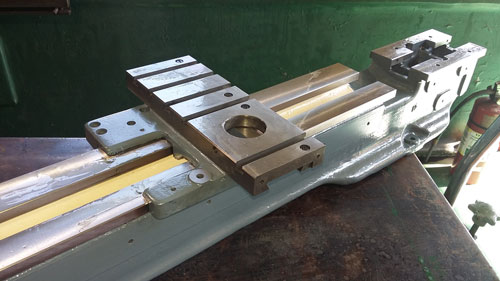

At the heart of all lathe and mill reconditioning, is the slideway grinding of the worn slides , to restore to original machine tool accuracy and tolerances .

Slideway grinding, and handscraping of the various configurations of vee, dovetails, square sections and trapezoidal ensures the hobby machine maintains it’s original manufacturer tolerances, for the accuracy required in the varied machining operations carried out .

Our factory facilities house 2 Slideway Grinders , with the large 5m capacity grinder required for heavy industry production reconditioning and lathes 3m – 5m . Also excellent for special design configurations such as machining centres / mills , and column style vee & flat sections .

The smaller Slideway Grinder ( 2m-3m ) is dedicated to small machine tools, with the hobby maker’s and small toolroom’s varied range of Myfords, Hercus, Colchester , Bridgeports , and all other genuine machine tools .

With our inhouse facilities , we can commit to our full MTA capabilities –

- Slideway grinding & handscraping Myford, Hercus , Colchesters , Bridgeports

- TURCITE molyglass wear strip fitment, Ph Br wear strip fitments .

- Oil gallery re-machining